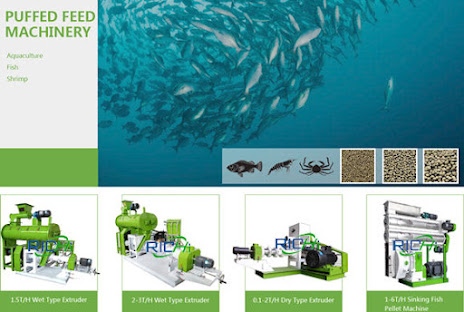

Drifting fish feed making equipment line

The technical benefits accomplished by RICHI's initiatives in floating fish feed making makers throughout the years are completely shown in the drifting fish feed production line.

Basic procedure, simple to learn, accurate criterion control, to make sure that the product is completed in a specific temperature, stress, humidity as well as time.

Practical structure design, unique material, fast self-cleaning efficiency to ensure mechanical security and very easy upkeep, vibrant forms and also tastes to satisfy the needs of numerous fish pet dog food.

When selecting aquafeed drifting fish feed production line, you must initially recognize the many attributes of aquafeed:

( 1 ) Little pellet size. Due to the brief digestive system of aquatic animals as well as relevant physiological attributes, in order to speed up food digestion as well as absorption, the smashed pellet size of water feed must be smaller than that of livestock as well as fowl feed.

For instance, in the manufacturing of eel as well as shrimp feed, the pellet dimension must reach 80 mesh to 120 mesh.

Related post: Fish Feed Mill Machine

( 2) High healthy protein material and low carbohydrate material. The protein material of livestock and poultry feeds is generally less than 20%, while the healthy protein material of aquatic pet feeds is mostly 30% to 40%, and the protein material of turtle as well as eel feeds is as high as 65% to 70%.

( 3) The pellet feed has a portable framework, high cohesion and also water resistance, as well as the stability of the pellet feed in water for greater than 2 hours is needed for fish feed.

( 4) In the production of aquatic feed, cross-contamination is purely banned. Some basic materials need to be treated aseptically.

The selected floating fish feed making maker is very easy to tidy and also has much less deposit. Specifically in the manufacturing of floating feed, shrimp and also eel feed, various other sorts of feed must not be generated at the same time to prevent cross-production contamination.

To produce top quality marine feed, we should rely on clinical and also sensible handling modern technology and incorporate it with advanced, reliable and stable floating fish feed making maker. Hereof, the option of drifting fish feed making equipment is particularly vital.

Related post: https://aquafeedmachine.com/fish-feed-mill-machine-in-russia/

1. Process flow of fish feed production line:.

The floating fish feed making maker assembly line can refine pellet feeds such as pigs, cattle, sheep, rabbits, chickens, ducks, fish, etc. The typical processing approach is numerous times extra reliable, as well as it is suitable for large farms as well as floating fish feed mills to produce full-price feed and also the transformation of pellet feed plants.

It can additionally create saw wood pellets, wood powder pellets and straw pellets, and so on. It is a pellet processing unit with a high degree of automation. It is a floating fish feed making device that utilizes corn, soybean dish, wheat, sorghum, straw, yard, rice husk, etc as resources, squashes the raw products, and also straight presses them into pellets.

2. Attributes of fish feed pellet maker assembly line:.

① This collection of floating fish feed making makers embrace a vapor conditioner, so that the material can be fully developed and the quality of the pellets can be made sure.

② The primary drive adopts high-precision equipment drive, and also the output is about 20% greater than that of the belt drive type.

③ Imported premium bearings and also oil seals are chosen to guarantee secure operation, reduced noise and also high efficiency of the whole machine.

④ The feeder takes on regularity conversion electric motor to guarantee the high quality of pellet discharge.

⑤ A range of aperture ring dies are readily available for choice. The floating fish feed making maker ring dies have long life span, smooth granulation as well as excellent quality.

⑥ Compensation type serpentine spring coupling of global sophisticated degree, with novel structure, density, safety, low sound and low failure efficiency.

Related post: Feed mill factory in Russia

3. Floating fish feed machine assembly line process.

Drifting fish feed making device is normally selected according to the manufacturing scale, manufacturing selections, and also manufacturing procedure problems. Consequently, various floating fish feed mills usually utilize various equipment. Nevertheless, some basic drifting fish feed making device for feed handling is the same.

According to the drifting fish feed making device line procedure circulation, it typically consists of basic material getting and cleaning up devices, communicating devices, crushing tools, batching devices, mixing tools, floating pellet device, floating fish feed extruder maker, liquid spraying devices, ventilation and also dust removal equipment, packaging equipment and also central control system.

The raw material receiving as well as cleaning up devices mostly consists of weighbridges, key cleansing displays and cyndrical tube containers;.

Frequently made use of communicating devices are screw conveyors, container lifts, scrape conveyors, belt conveyors and also pneumatically-driven communicating equipment;.

Pulverizing tools consists of magnetic separator, feeder, pulverizer, and so on. Amongst them, there are lots of kinds of pulverizers, frequently used are hammer as well as claw pulverizers and also micro pulverizers that call for finer pulverization;.

The batching tools typically embraces digital automatic batching ranges; the types of mixers made use of are horizontal double-shaft (single-shaft) paddle mixers, straight screw mixers, vertical mixers and waistline drum mixers for the production of premixes;.

Granulation tools includes vapor boiler, conditioner, floating fish feed pellet mill, cooler, rating display as well as crusher, and so on;.

Drifting fish feed extruder machine consists of conditioner and also extruder; fluid spraying devices includes liquid storage tank, air pump and also flow meter;.

Ventilation as well as dirt elimination tools includes suction fans, brakes as well as dirt collectors, and so on; packaging devices includes packaging ranges, sealing devices, and so on;.

The main control system is the " mind" of the whole floating fish feed making device line processing process, where the control systems of different tools are concentrated.

4. Quality control of floating fish feed making maker.

( 1 ) Equipment pre-design control.

The technological team will certainly perform scientific and also practical layout according to the real conditions as well as requirements of the consumer's workshop, power, place, and so on, integrated with the drifting fish feed making device test circumstance.

( 2 ) Extra parts option standards.

Spare components vendors, purely screen the supplier's items, as well as select high-quality as well as low-cost makers in the very same sector. On the premise of making certain high quality, decrease drifting fish feed making maker manufacturing prices and also absolutely allow clients to acquire cost-effective equipment. For outsourced parts of the same range, there are less than three suppliers assured, to ensure that the fittest can be bought.

( 3 ) Production control.

After the sales division obtains the order, it will be submitted to the technical department, and also the technical department will create the CAD drawings representing the drifting fish feed making machine according to the order details. The manufacturing department arranges a appropriate component to acquire, create as well as process according to the technological records of CAD drawings.

( 4 ) Equipment and also spare parts approval.

There are full time quality control personnel to perform set examination of outsourcing as well as outsourcing components. Quality examination is executed for vital as well as precise spare parts. For self-made parts, self-inspection, shared examination and general inspection of handling personnel need to be carried out, and all certified components can be put into use.

After the ended up drifting fish feed making equipment is installed, it will certainly be approved by after-sales specialists. On-site tools can be loaded for on-site debugging only after no-load operation for more than half an hour and no faults. Make certain that each equipment meets the floating fish feed mill manufacturing facility problems as well as release the drifting fish feed making machine certification.

For details please contact: fish feed machine

WhatsApp:86 138 3838 9622

Email:enquiry@aquafeedmachine.com

Comments

Post a Comment